So on this fine day, I decided to get to work on the wiring and electronics bay for my little Astromech buddy. This will make showing his moves off a little more easy, as getting my ad-hoc wiring together in the past was quite a chore.

First off, I had to get the rear support bars in position so the threaded holes were facing front to back. Who knew that the whole top plate would have to come off for this ? When I first assembled the frame a couple of months ago, I knew what these threaded holes were for, but I did not think to line them up at the time.

I started with a good old fashioned cutting board. (No, Mom, I did not use one of yours, I got this one at the Wal-Marts) Drilled holes for the screws, and had to cut some slots to allow the center ring to fit in.

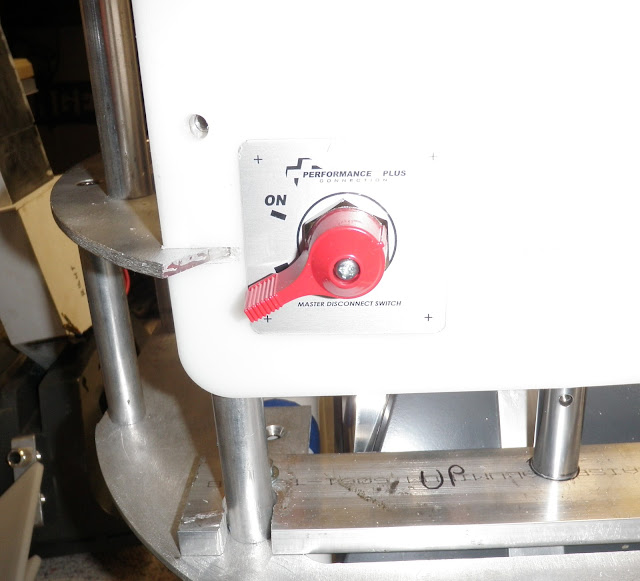

The first piece installed was the main power switch. This thing is big, but I had ordered a good quality switch from Amazon that would handle 50 amps and 24Volts. Apparently, these are used for automobiles, and they are quite robust.

Before we get to all the wiring, there are a couple of tools that I picked up, and bacon-saver is the flavor of these handy little numbers.

First up, a self-adjusting wire stripper. This thing just plain works. Put the wire in the jaws, set it to the right length that you wish to strip, pull - and there you go. A really great tool that makes all of the wiring a simple chore. I wanted to make the electronics bay as clean as possible, and no way would I have been so accurate and neat with the wire stripping with the traditional strippers.

Next up, a ratcheting wire-end crimping tool. Again, this thing made short work of crimping the wire ends, and they all look identical.

The last tool is the Anderson Power pole crimping tool. I wish I could have used more of the power-pole connectors, but most of the wiring is... uh ...... hard-wired, so quick disconnects are not really required.

I picked up a 16 bay distribution and fuse box... OVERKILL is the name of this game. I have no idea why I got this unit. There was an 8 bay box available, but why not go with 16 ? The truth is, this unit will handle the 24 volt power supply, and all I have running off the 24 volt supply is the leg motors and the dome motor. I may pick up 2 of the 8 bay boxes and use one for 24 volt service and the other for the stepped-down 12 volt power, as I will have a number of items that need to be powered with 12 volts.

The two switches above the fuse box are for the power leads to the motors. The motor controller has regenerative braking, which means the breaking of the wheels sends power back into the system. (At least this is what I think I read...) The bottom line is that if you have the droid powered up, and you push the little guy, the power from the wheels can feed back into the power matrix, and POOF, you can blow the motor controller. The switches shut off the power between the motor controller and the actual drives.

You can see in the bench test that the switches are lit with green LEDs. This little project kicked my hiney a bit. I figured that the switches would illuminate when they were on... these switches have lights that are on ALL of the time. It was pretty difficult finding a 30 amp switch that handled 24 volts AND had the added bling of lights. Oh well - I am not sure when and why I will need to use these switches, but they look cool, and I learned a bit about wiring switches in the process.

Here is the motor controller mounted up. The Leads that I am holding will serve the scooter motors with power. I used the Anderson Power-Pole connectors on these, so I can disconnect the power and remove the legs easily.

A side view showing the nylon stand-offs that hold the motor controller off of the bay's board.

A little later, and the RC receiver and Dome motor controller are installed. This power is being supplied by the 2 12 volt batteries. WOOT !

I had to be very conscious of where the wires ran in the back of the board, because the board is VERy close to the rails that the center leg travels up and down on. I HOPE HOPE HOPE that I did not mount anything that will interfere with the outer skins. I threw caution to the wind on this one, using my keen eyesight and sense of distance to gauge where the electronics needed to fit in order to stay out of the way of the skins. Only time will tell on this.... and if it is a fail, you may hear the expletives wherever you may roam.

The current state of the wiring inside the body. A little ramshackle at the moment, as I need to find out exactly where the wires need to go so I can A: Easily remove the board for access to the inner-sanctum and B: allow for free travel of the center leg. It is really amazing how quickly the space gets filled up inside this little guy.

Of course, I had to test out the power and new drive train(s). Gotta say, that I am very happy with the results. He moves, and nothing blew up, do I call that a victory. The new scooter motor holders have a little issue. I thing the caster on the legs may be a little high, as I found myself losing traction on the carpet. This happened with the other holders, and was resolved with a little tweak to the angle of the center foot.

I got the aluminum bling mounted on the legs tonight as well. Forgot my ankle cylinders.... I will get them on tomorrow. Also sanded the horseshoes and they are dangerously close to paint - along with the rest of the leg pieces/parts.

Who knows what tomorrow will bring, I only have 2,017 more things to do. Stay tuned, and see what I get into.

Liking your build so far. Where did you get the 24V compatible distribution fuse box?

ReplyDeleteHi Steve,

DeleteI got the fuse box at amazon. Here is the link....

http://www.amazon.com/Blue-Sea-Systems-Blade-Block/dp/B001P6FTHC/ref=sr_1_6?ie=UTF8&qid=1360806238&sr=8-6&keywords=fuse+box

(It is on sale now to boot)